Artcraft Ultrasonic Cleaning Baskets

Why do all of the major Ultrasonic Cleaning Systems and Optics Manufacturers specify Artcraft racks?

As more and more products use optics the need for ultrasonic cleaning has grown exponentially. The process involves placing the items in a parts washer basket, immersing them in a cleaning solution and using high frequency vibrations to blast the surface and remove any contaminants.

This cleaning process is very effective but presents several challenges that Artcraft parts cleaning racks successfully resolve.

Problem: Optic Fixture Surface Damage

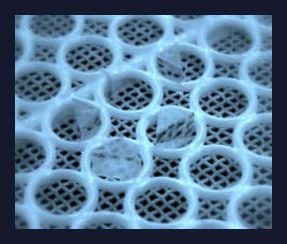

When cleaning small parts such as optics the intense vibration often causes parts to collide and end up scratching each other, requiring additional processes to remove any flaws.

Artcraft Solution:

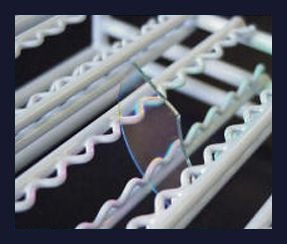

Artcraft's racks are engineered so none of the pristine optic fixture surfaces touch the side of the racks. In addition, these stainless steel racks are either electro polished or coated with Haylar or Nylabond to protect the parts, as well as survive the chemicals used in the process.

Problem: Optics Parts Falling Out of the Parts Washer Basket

Whenever you submerge parts in the cleaning solution, there is a chance they can fall or float out of the ultrasonic cleaning fixture. Loose parts may become damaged or damage the equipment.

Artcraft Solution:

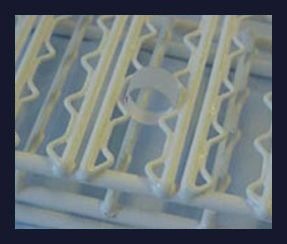

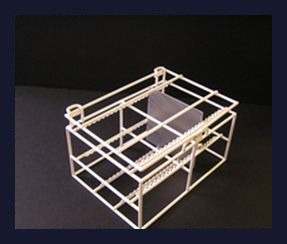

By designing lids that snap and securely shut, Artcraft racks are designed to safely house even most delicate prisms and optics as small as 3mm x 3mm. Custom handles may be added either or both sides so the rack is usable in an automated system or picked up by hand.

Ultrasonic Cleaning fixtures Custom Engineered for Optimal Cleaning

One size does not fit all: Each Artcraft rack is custom engineered to optimize your cleaning system carrier and enable you to safely clean multiple size parts at the same time. Their lightweight designs reduce the tool mass but are sturdy enough to last.

With no minimum orders and short lead times, the cleaning rack is just a click away.